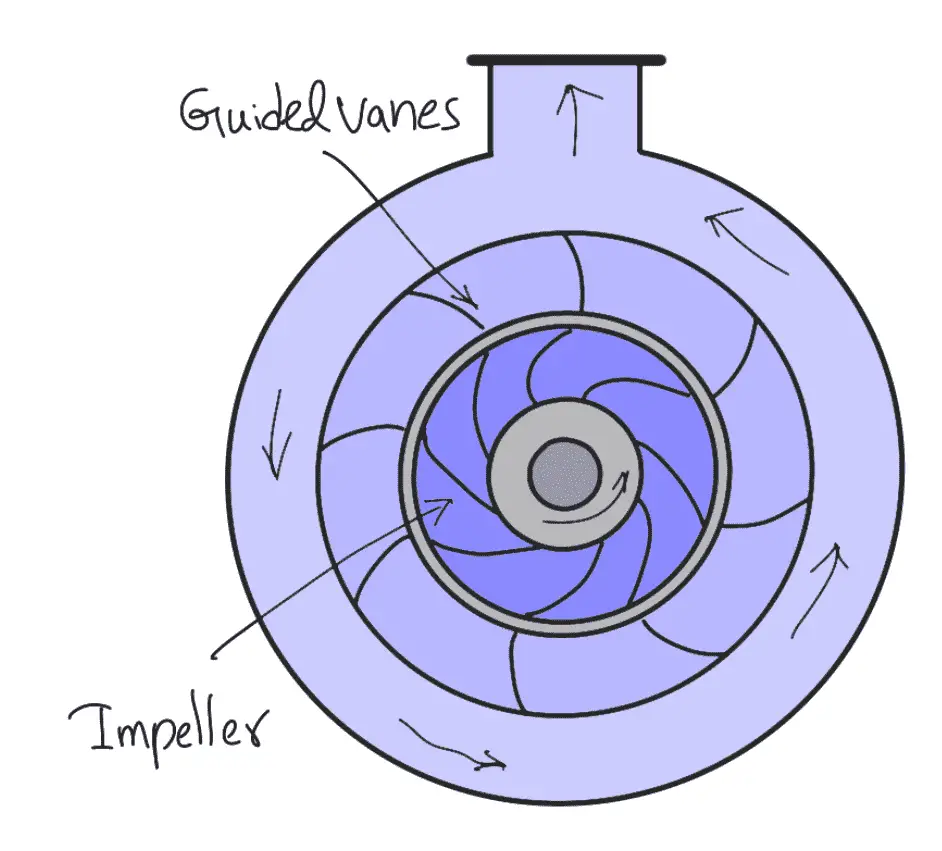

Different Types Of Casing In Centrifugal Pump . There two basic types of pump casings: #1 shaft and shaft sleeve. Whether we’re talking about volutes or diffusers, what all casings have in common is that they are designed to take. Tangential discharge casings have a discharge flange centerline that is in a plane offset from the pump’s centerline. Almost every pump type has a different casing type by which it can be recognised. Centrifugal pump casing is simply like an airtight passage. The shaft is a central part of the pump, which rotates with the connected impeller. This is housed the pump impeller and helped to convert the kinetic energy of the impeller into the. The three basic casing types primarily used for centrifugal pumps are the single volute, double volute and vaned diffuser. When selecting a centrifugal pump, it’s important to consider the types of casing available. With increasing specific speeds, the following casing.

from extrudesign.com

The three basic casing types primarily used for centrifugal pumps are the single volute, double volute and vaned diffuser. #1 shaft and shaft sleeve. The shaft is a central part of the pump, which rotates with the connected impeller. There two basic types of pump casings: When selecting a centrifugal pump, it’s important to consider the types of casing available. Whether we’re talking about volutes or diffusers, what all casings have in common is that they are designed to take. Centrifugal pump casing is simply like an airtight passage. With increasing specific speeds, the following casing. Tangential discharge casings have a discharge flange centerline that is in a plane offset from the pump’s centerline. This is housed the pump impeller and helped to convert the kinetic energy of the impeller into the.

How does Centrifugal Pump Work? ExtruDesign

Different Types Of Casing In Centrifugal Pump This is housed the pump impeller and helped to convert the kinetic energy of the impeller into the. Centrifugal pump casing is simply like an airtight passage. Tangential discharge casings have a discharge flange centerline that is in a plane offset from the pump’s centerline. #1 shaft and shaft sleeve. The three basic casing types primarily used for centrifugal pumps are the single volute, double volute and vaned diffuser. The shaft is a central part of the pump, which rotates with the connected impeller. There two basic types of pump casings: Whether we’re talking about volutes or diffusers, what all casings have in common is that they are designed to take. Almost every pump type has a different casing type by which it can be recognised. This is housed the pump impeller and helped to convert the kinetic energy of the impeller into the. When selecting a centrifugal pump, it’s important to consider the types of casing available. With increasing specific speeds, the following casing.

From acoem.us

Basics of Centrifugal Pumps Know Your Machines Acoem USA Different Types Of Casing In Centrifugal Pump Almost every pump type has a different casing type by which it can be recognised. #1 shaft and shaft sleeve. Whether we’re talking about volutes or diffusers, what all casings have in common is that they are designed to take. This is housed the pump impeller and helped to convert the kinetic energy of the impeller into the. The shaft. Different Types Of Casing In Centrifugal Pump.

From startitnew.blogspot.com

start learning something new here CENTRIFUGAL PUMPS Different Types Of Casing In Centrifugal Pump Centrifugal pump casing is simply like an airtight passage. Almost every pump type has a different casing type by which it can be recognised. The shaft is a central part of the pump, which rotates with the connected impeller. Whether we’re talking about volutes or diffusers, what all casings have in common is that they are designed to take. With. Different Types Of Casing In Centrifugal Pump.

From www.mecholic.com

volute casing Different Types Of Casing In Centrifugal Pump Almost every pump type has a different casing type by which it can be recognised. This is housed the pump impeller and helped to convert the kinetic energy of the impeller into the. Tangential discharge casings have a discharge flange centerline that is in a plane offset from the pump’s centerline. The three basic casing types primarily used for centrifugal. Different Types Of Casing In Centrifugal Pump.

From www.mecholic.com

Vortex casing Different Types Of Casing In Centrifugal Pump The shaft is a central part of the pump, which rotates with the connected impeller. Whether we’re talking about volutes or diffusers, what all casings have in common is that they are designed to take. This is housed the pump impeller and helped to convert the kinetic energy of the impeller into the. When selecting a centrifugal pump, it’s important. Different Types Of Casing In Centrifugal Pump.

From www.iqsdirectory.com

Centrifugal Pumps Types, Applications, Benefits, and Maintenance Different Types Of Casing In Centrifugal Pump #1 shaft and shaft sleeve. The three basic casing types primarily used for centrifugal pumps are the single volute, double volute and vaned diffuser. There two basic types of pump casings: Centrifugal pump casing is simply like an airtight passage. The shaft is a central part of the pump, which rotates with the connected impeller. With increasing specific speeds, the. Different Types Of Casing In Centrifugal Pump.

From www.mechanical-knowledge.com

Introduction To Centrifugal Pumps Pdf Different Types Of Casing In Centrifugal Pump #1 shaft and shaft sleeve. When selecting a centrifugal pump, it’s important to consider the types of casing available. There two basic types of pump casings: Almost every pump type has a different casing type by which it can be recognised. The shaft is a central part of the pump, which rotates with the connected impeller. With increasing specific speeds,. Different Types Of Casing In Centrifugal Pump.

From multiphase-corp.com

SPLIT CASING CENTRIFUGAL PUMPS Multiphase Corporation Different Types Of Casing In Centrifugal Pump Whether we’re talking about volutes or diffusers, what all casings have in common is that they are designed to take. Centrifugal pump casing is simply like an airtight passage. When selecting a centrifugal pump, it’s important to consider the types of casing available. Almost every pump type has a different casing type by which it can be recognised. The shaft. Different Types Of Casing In Centrifugal Pump.

From www.youtube.com

( हिन्दी ) CENTRIFUGAL PUMP WORKING & TYPES OF CASING ANUNIVERSE 22 Different Types Of Casing In Centrifugal Pump Almost every pump type has a different casing type by which it can be recognised. With increasing specific speeds, the following casing. There two basic types of pump casings: #1 shaft and shaft sleeve. Whether we’re talking about volutes or diffusers, what all casings have in common is that they are designed to take. When selecting a centrifugal pump, it’s. Different Types Of Casing In Centrifugal Pump.

From www.mechanicaltutorial.com

Centrifugal Pump Different Types And Application Of Centrifugal Pump Different Types Of Casing In Centrifugal Pump When selecting a centrifugal pump, it’s important to consider the types of casing available. Tangential discharge casings have a discharge flange centerline that is in a plane offset from the pump’s centerline. Almost every pump type has a different casing type by which it can be recognised. The shaft is a central part of the pump, which rotates with the. Different Types Of Casing In Centrifugal Pump.

From www.linquip.com

Types of Pump Casings (In Centrifugal Pumps & Others) + Pros & Cons Different Types Of Casing In Centrifugal Pump This is housed the pump impeller and helped to convert the kinetic energy of the impeller into the. Tangential discharge casings have a discharge flange centerline that is in a plane offset from the pump’s centerline. Almost every pump type has a different casing type by which it can be recognised. There two basic types of pump casings: The shaft. Different Types Of Casing In Centrifugal Pump.

From ulsterdogfence.com

Centrifugal Pump Working and Types A Complete Guide (2023) Different Types Of Casing In Centrifugal Pump There two basic types of pump casings: This is housed the pump impeller and helped to convert the kinetic energy of the impeller into the. Tangential discharge casings have a discharge flange centerline that is in a plane offset from the pump’s centerline. Almost every pump type has a different casing type by which it can be recognised. The three. Different Types Of Casing In Centrifugal Pump.

From www.sintechpumps.com

Pump Casing Manufacturers Sintech Pumps India Different Types Of Casing In Centrifugal Pump This is housed the pump impeller and helped to convert the kinetic energy of the impeller into the. The shaft is a central part of the pump, which rotates with the connected impeller. When selecting a centrifugal pump, it’s important to consider the types of casing available. #1 shaft and shaft sleeve. There two basic types of pump casings: Almost. Different Types Of Casing In Centrifugal Pump.

From proper-cooking.info

Centrifugal Pump Casing Types Different Types Of Casing In Centrifugal Pump When selecting a centrifugal pump, it’s important to consider the types of casing available. There two basic types of pump casings: The three basic casing types primarily used for centrifugal pumps are the single volute, double volute and vaned diffuser. #1 shaft and shaft sleeve. This is housed the pump impeller and helped to convert the kinetic energy of the. Different Types Of Casing In Centrifugal Pump.

From www.researchgate.net

1. Main components of a centrifugal pump (Taken from [47]) Download Different Types Of Casing In Centrifugal Pump With increasing specific speeds, the following casing. When selecting a centrifugal pump, it’s important to consider the types of casing available. Tangential discharge casings have a discharge flange centerline that is in a plane offset from the pump’s centerline. This is housed the pump impeller and helped to convert the kinetic energy of the impeller into the. The shaft is. Different Types Of Casing In Centrifugal Pump.

From extrudesign.com

How does Centrifugal Pump Work? ExtruDesign Different Types Of Casing In Centrifugal Pump #1 shaft and shaft sleeve. When selecting a centrifugal pump, it’s important to consider the types of casing available. The three basic casing types primarily used for centrifugal pumps are the single volute, double volute and vaned diffuser. Centrifugal pump casing is simply like an airtight passage. The shaft is a central part of the pump, which rotates with the. Different Types Of Casing In Centrifugal Pump.

From theconstructor.org

Centrifugal Pump Components, Working, Types and Application Different Types Of Casing In Centrifugal Pump Almost every pump type has a different casing type by which it can be recognised. #1 shaft and shaft sleeve. Whether we’re talking about volutes or diffusers, what all casings have in common is that they are designed to take. There two basic types of pump casings: Tangential discharge casings have a discharge flange centerline that is in a plane. Different Types Of Casing In Centrifugal Pump.

From proper-cooking.info

Centrifugal Pump Casing Types Different Types Of Casing In Centrifugal Pump Centrifugal pump casing is simply like an airtight passage. There two basic types of pump casings: When selecting a centrifugal pump, it’s important to consider the types of casing available. #1 shaft and shaft sleeve. This is housed the pump impeller and helped to convert the kinetic energy of the impeller into the. The three basic casing types primarily used. Different Types Of Casing In Centrifugal Pump.

From americanadenoticias.com

Double Suction Centrifugal Pump Diagram A Comprehensive Guide to Different Types Of Casing In Centrifugal Pump When selecting a centrifugal pump, it’s important to consider the types of casing available. Whether we’re talking about volutes or diffusers, what all casings have in common is that they are designed to take. Tangential discharge casings have a discharge flange centerline that is in a plane offset from the pump’s centerline. With increasing specific speeds, the following casing. This. Different Types Of Casing In Centrifugal Pump.